Se esses cabos falharem, o robô inteiro pode parar de funcionar. É por isso que protegê-los é mais importante do que a maioria das pessoas imagina.

O que acontece se a fiação do robô não estiver protegida?

A fiação dentro dos robôs enfrenta dificuldades. Sem a proteção adequada, você corre o risco de: Fios raspando em bordas afiadas e quebrando.

Esses pequenos problemas podem resultar em reparos caros ou paralisações totais, especialmente em ambientes onde o tempo de atividade é essencial.

Nosso BRS-PA66 Mangas trançadas expansíveis de nylon da série oferece uma solução simples e econômica. Envolve os cabos como uma armadura flexível, protegendo-os de ameaças externas e mantendo tudo organizado.

Principais benefícios:

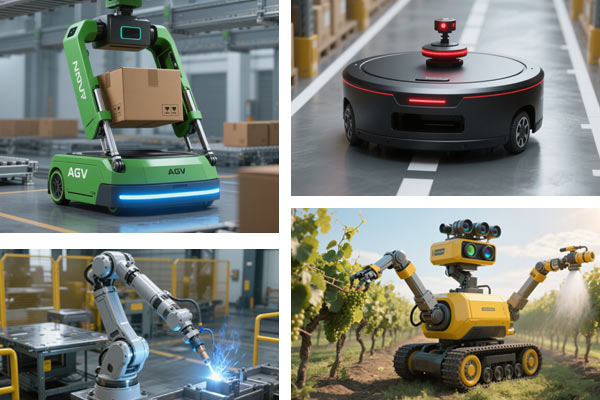

Seja um robô agrícola navegando por videiras ou um robô de armazém gerenciando entregas, a capa protege os sistemas mais críticos:

| Robôs são um | O que é Pr detecta |

| Módulos de bateria | EU isolamento contra calor e bordas afiadas |

| Conexões do motor | Danos por vibração, atrito e movimento |

| Fiação do sensor | Interferência de sinal e desgaste mecânico |

| Circuitos de controle | Clareza de roteamento interno e acesso de manutenção |

| Acessórios para ferramentas | Torcer, puxar e movimentos repetidos |

Por que é um pequeno detalhe que causa um grande impacto

O uso de revestimento trançado de alta qualidade não protege apenas os fios, mas também prolonga a vida útil do robô , reduz custos de manutenção , e aumenta a confiabilidade do sistema .

É por isso que os principais engenheiros de robótica fazem da capa parte do projeto desde o primeiro dia — e não como uma reflexão tardia.

Quer você esteja projetando automação de última geração, adaptando sistemas mais antigos ou melhorando a confiabilidade em condições adversas, nossa capa trançada BRS-PA66 pode ajudar.